Plastic injection molding is the process of forming a thermoplastic material into a desired shape that requires a machine and tooling. Injection molding is an industrial process of molten thermoplastic materials being injected into a mold cavity using an injection screw or ram. This process allows Maryland Plastic Products to manufacture simple or complex parts at high speed. Injection molding also guarantees that every part you produce is going to be practically identical to the first one. This is a great characteristic when producing brand consistency and part reliability in large quantities.

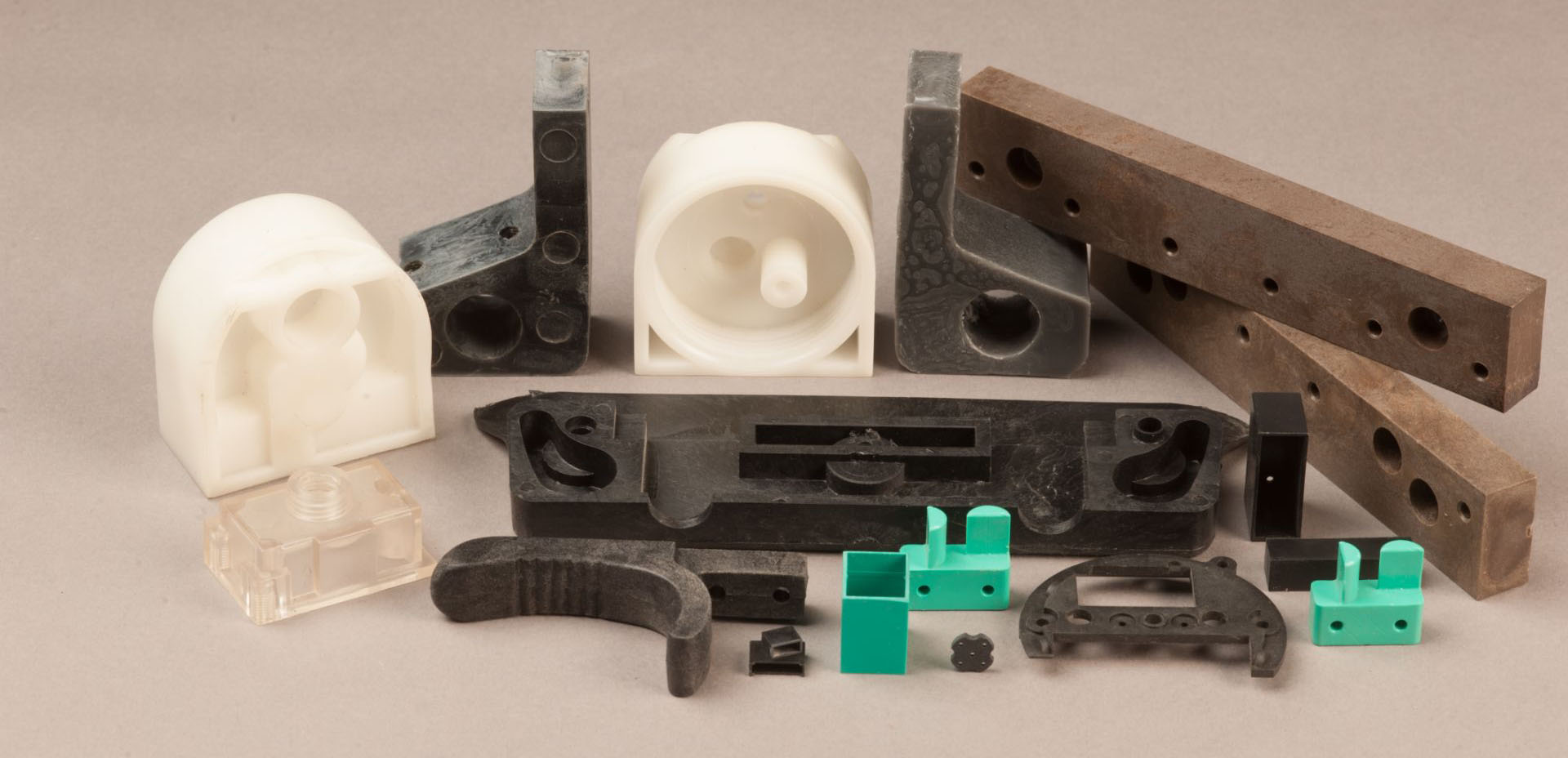

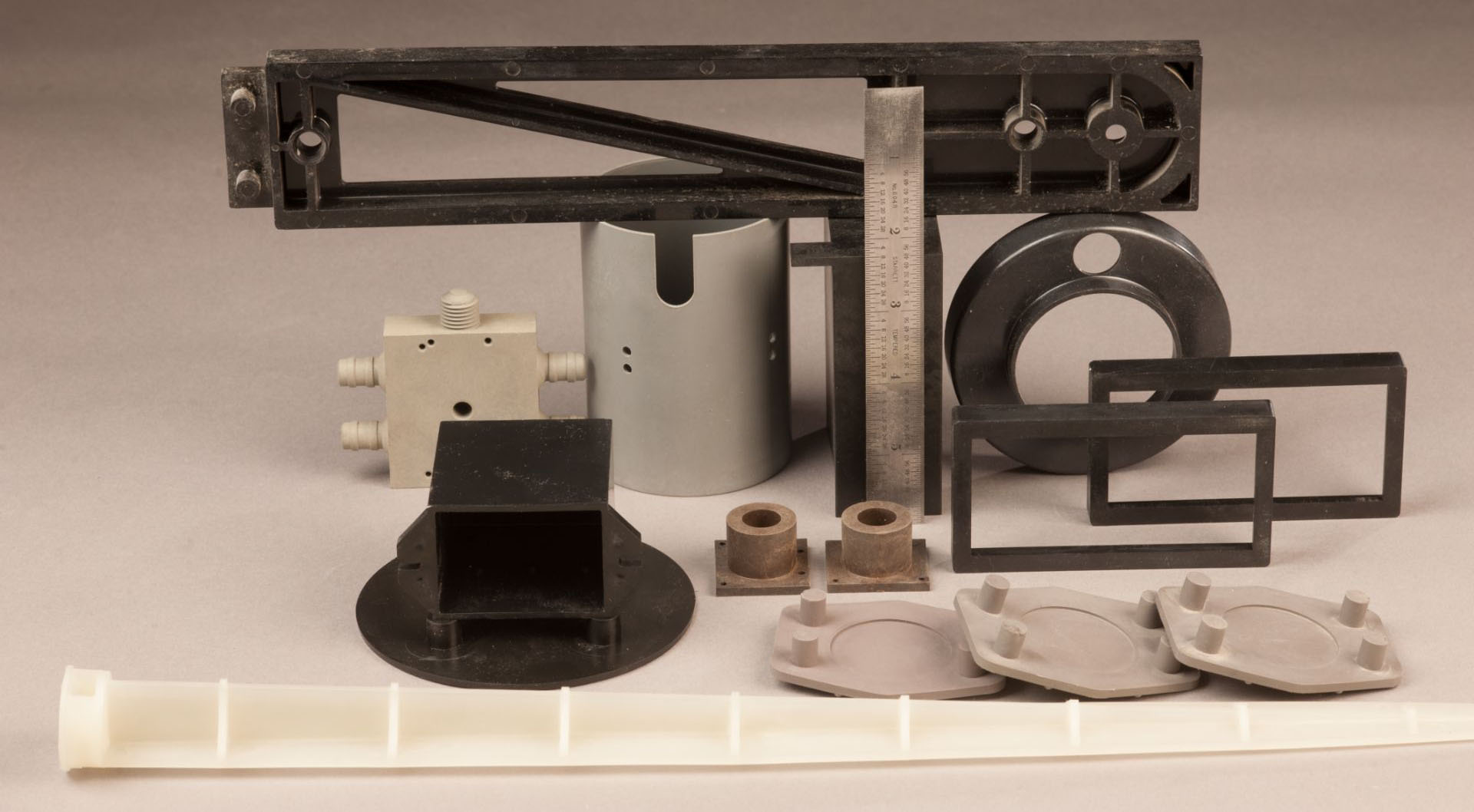

Maryland Plastic Products has injection molding machines/presses from 30 ton to 200 ton (amount of clamping force they can generate). A variety of thermal plastics (thermoset/thermoplastic materials) can be utilized to for a wide assortment of applications. Injection molding gives Maryland Plastic the ability to produce custom products of any size, shape or color in large volume in a short amount of time. Accessory fabrications are also available to facilitate any special requirements. If a part requires matching plastic covers, colors, or finishes we are able to provide that for all applications.

Tooling for injection molding can be done on-site in our in-house tool shop. Having an in-house tool shop allows us to cut tooling time and save our customers money. Our experience in the injection molding industry allows us to share our knowledge of molding with customers as they design a product. Our main goal is to help create a high-quality mold that is efficient, long lasting, easy to operate and maintain and meets all specifications at the lowest cost possible.